LAMINATED FOAM

Laminated is also known as gluing two flats surfaces.

Inlays from laminated foams have multiple uses:

- When we want to soft foam reinforce and stiffen in the upper layer.

- When we place more products in the box and we want them to be labeled

- When we want to change the colour/ looks of the foam (e.g. laminated with flocked material)

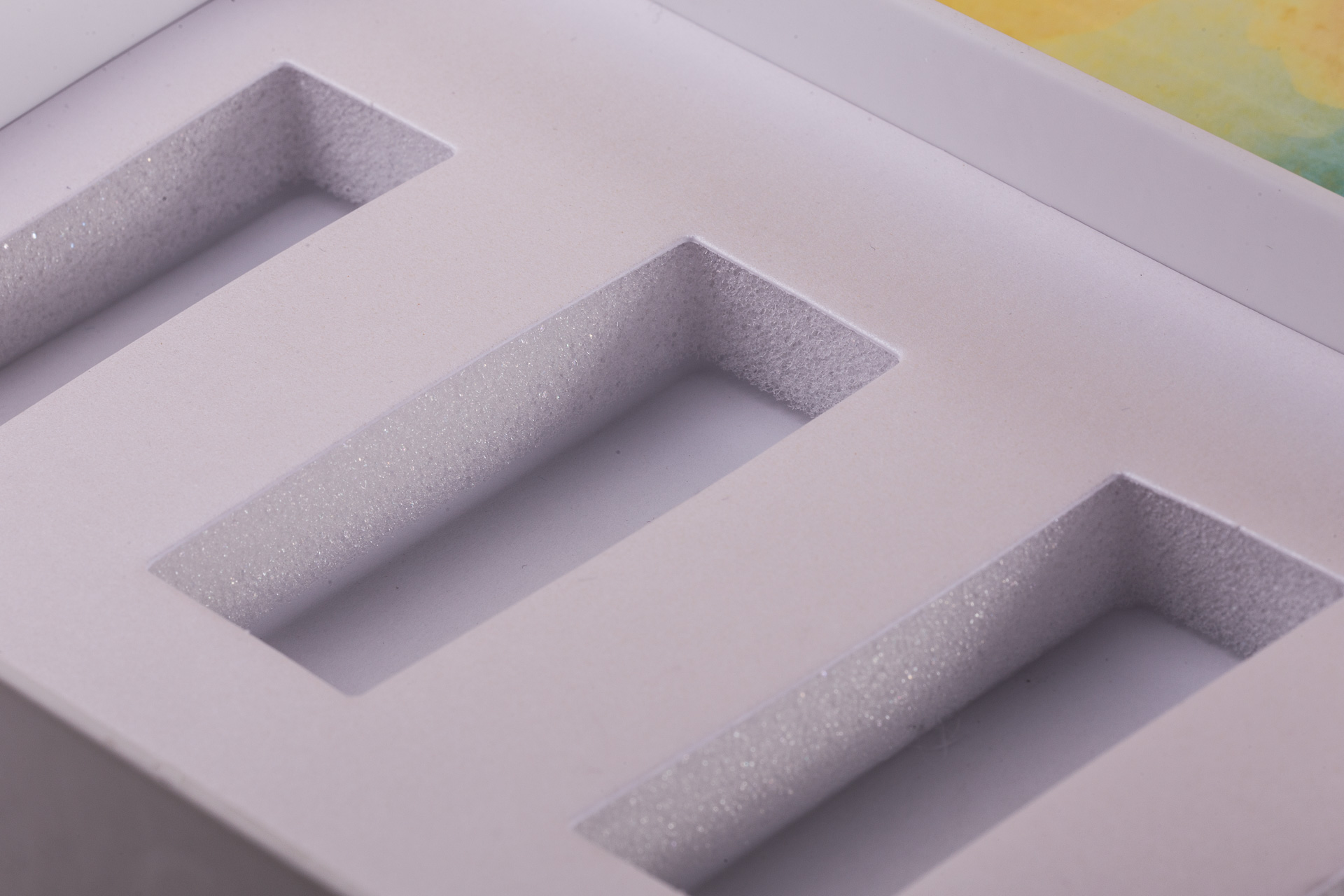

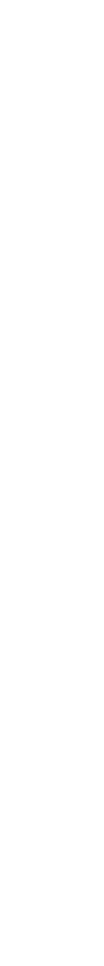

Soft foam PU T18 is white and laminated with white paper.

Due to the high price of high density white foam is usually less expensive then using dense foam. It sholud b noted that white PU foam is sensitive to UV light and when is exposed to sunlight over time it will yellow, however in closed box it maintanies its whiteness for yeras.

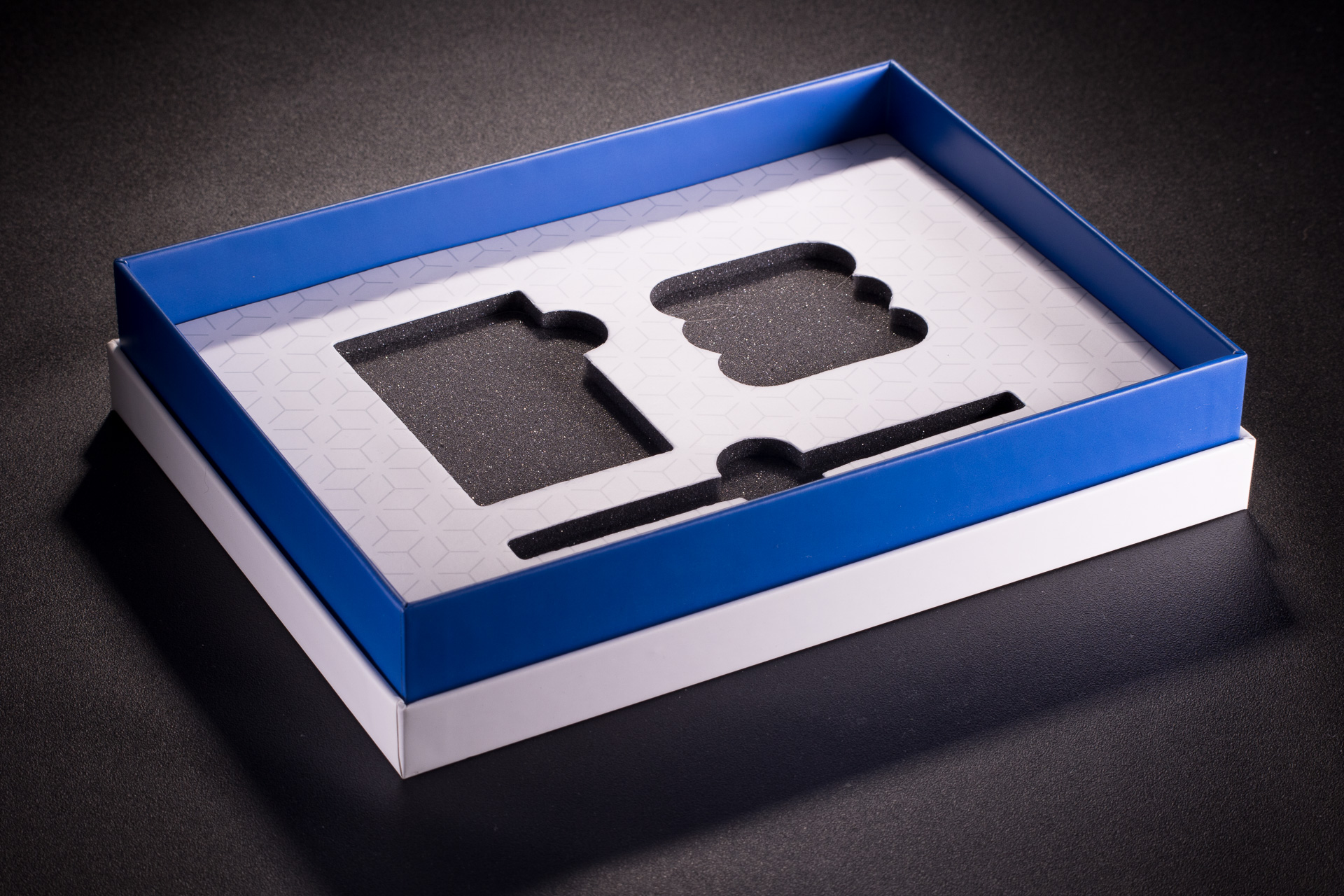

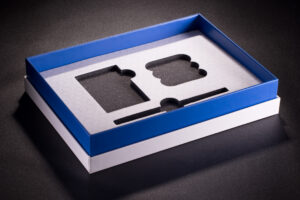

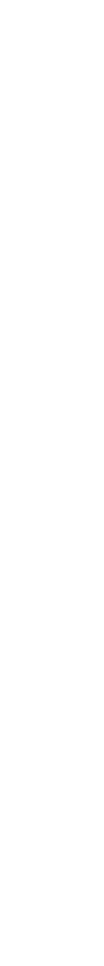

The solution that in the photo next to it is similar to the solution above. The solution that was used here is laminated cardboard 300g wiht prinitg on the dense black EVA foam.

Printing was made from screen printing. Its allows for additional labeling and identification of similar elements embedded in the padding.

Example of inlay made from soft PU 23 foam in gray color. Foam is laminated whit crepe paper with wallpaper printing. In this case the print was meant to be only decorative to match with the graphics on the outside of the box. Typically to get that type of look is to laminated paper with a laminate that matches the covering of outside part of the box.

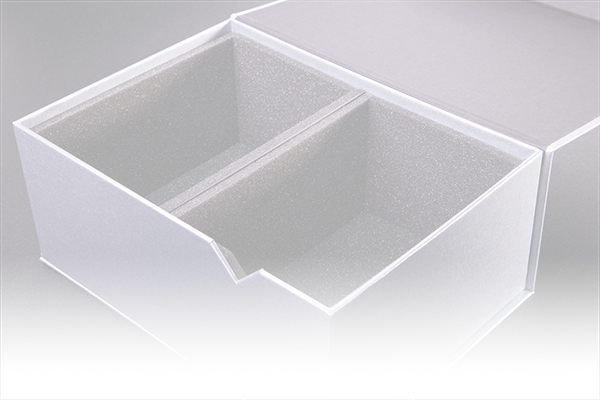

Box bottom-lid made of layered foam. We use here flocked materail for laminating on both Flocked material is very elegant finish. Usually it comes in a limited color range. Most commonly it is used in black.