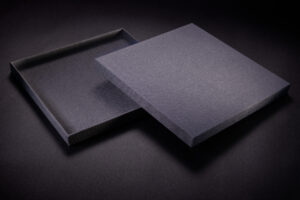

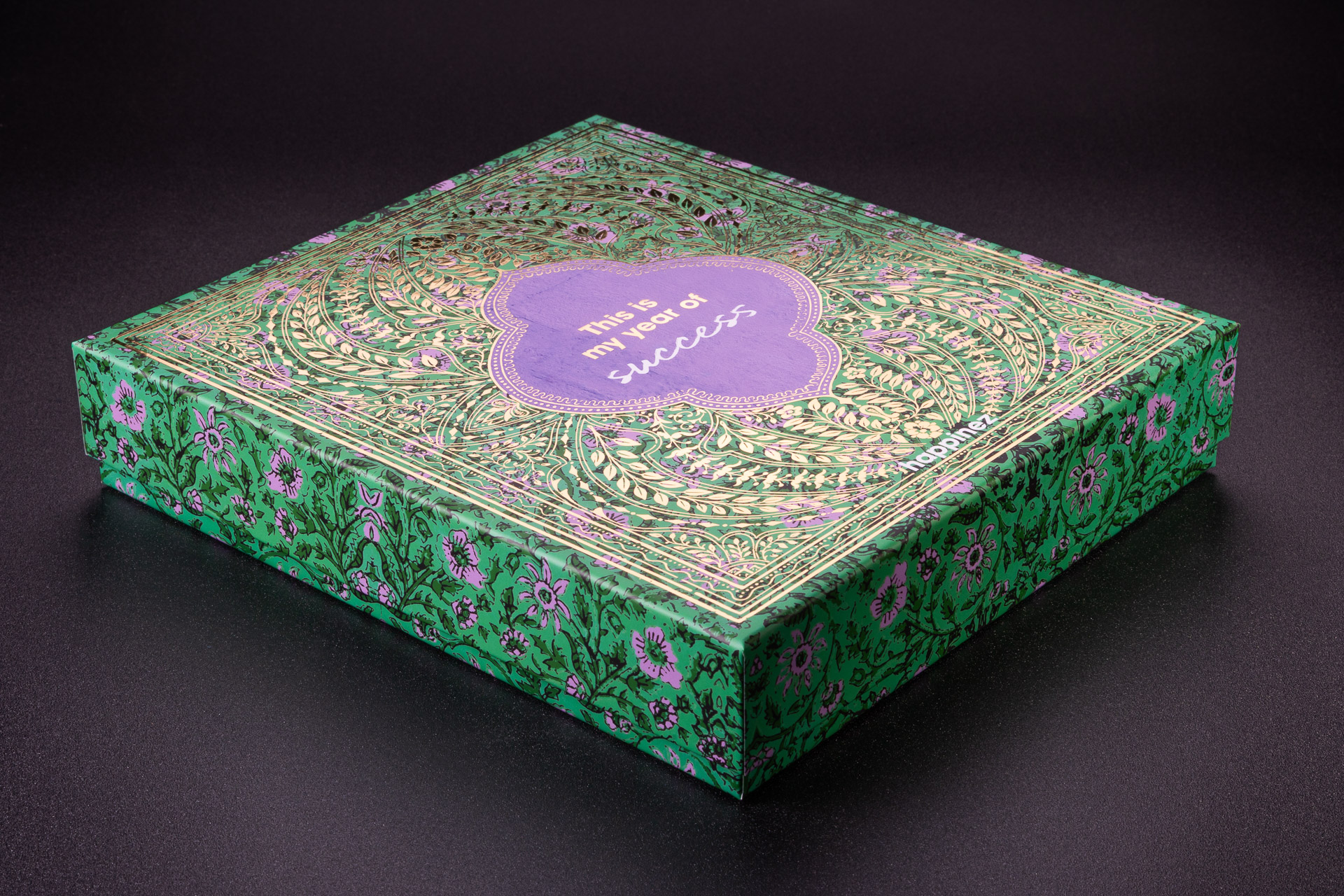

BOTTOM-LID BOX (PSW)

This is the most popular type of wrapped box.

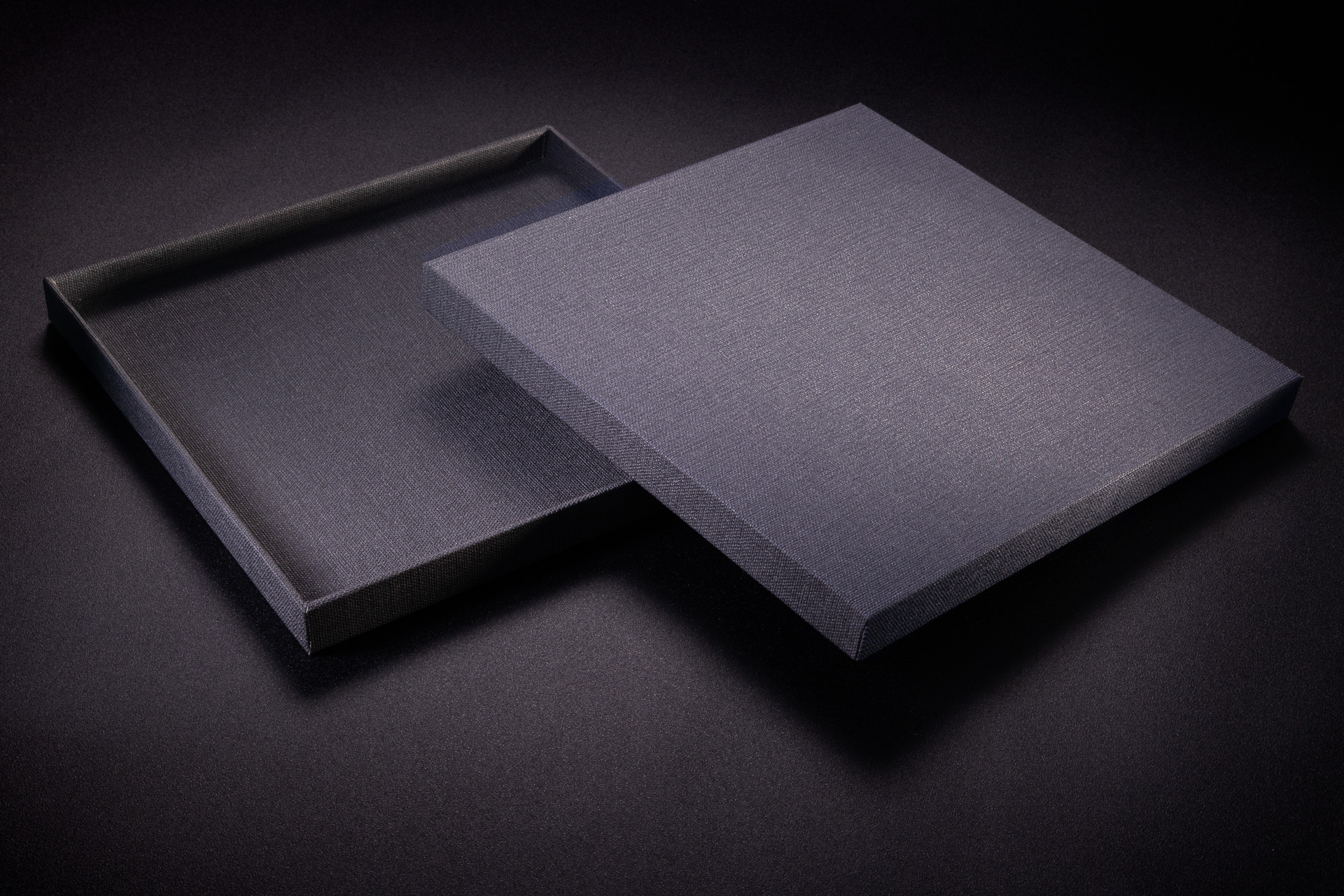

The box consists of two similar bodies, one of which is the bottom and the other is the lid.

These boxes are used in many applications.

They are packed in:

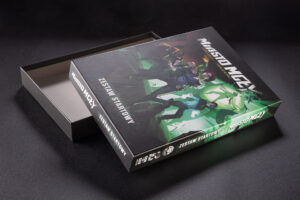

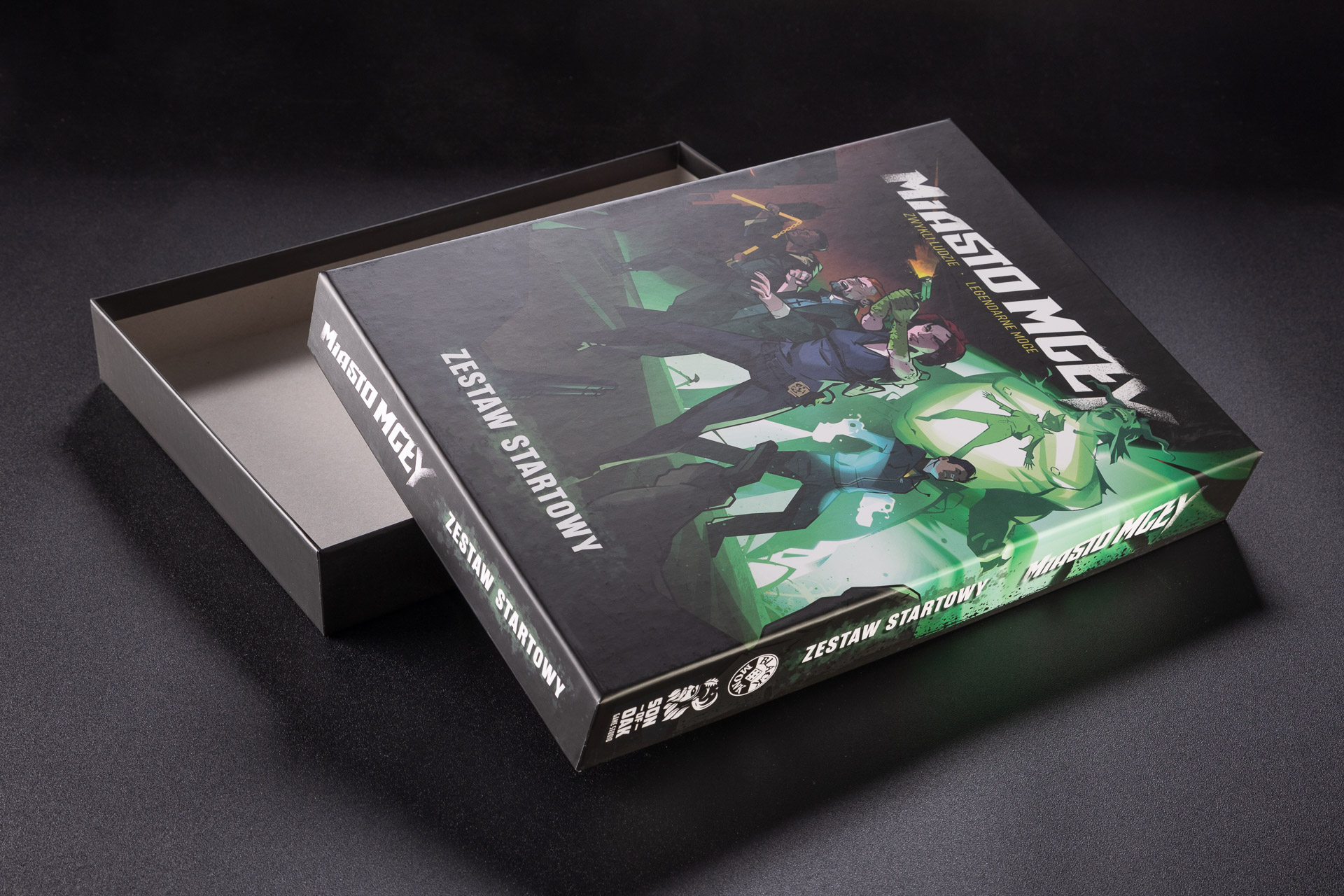

- games and cards

- shoes

- books

- clothing

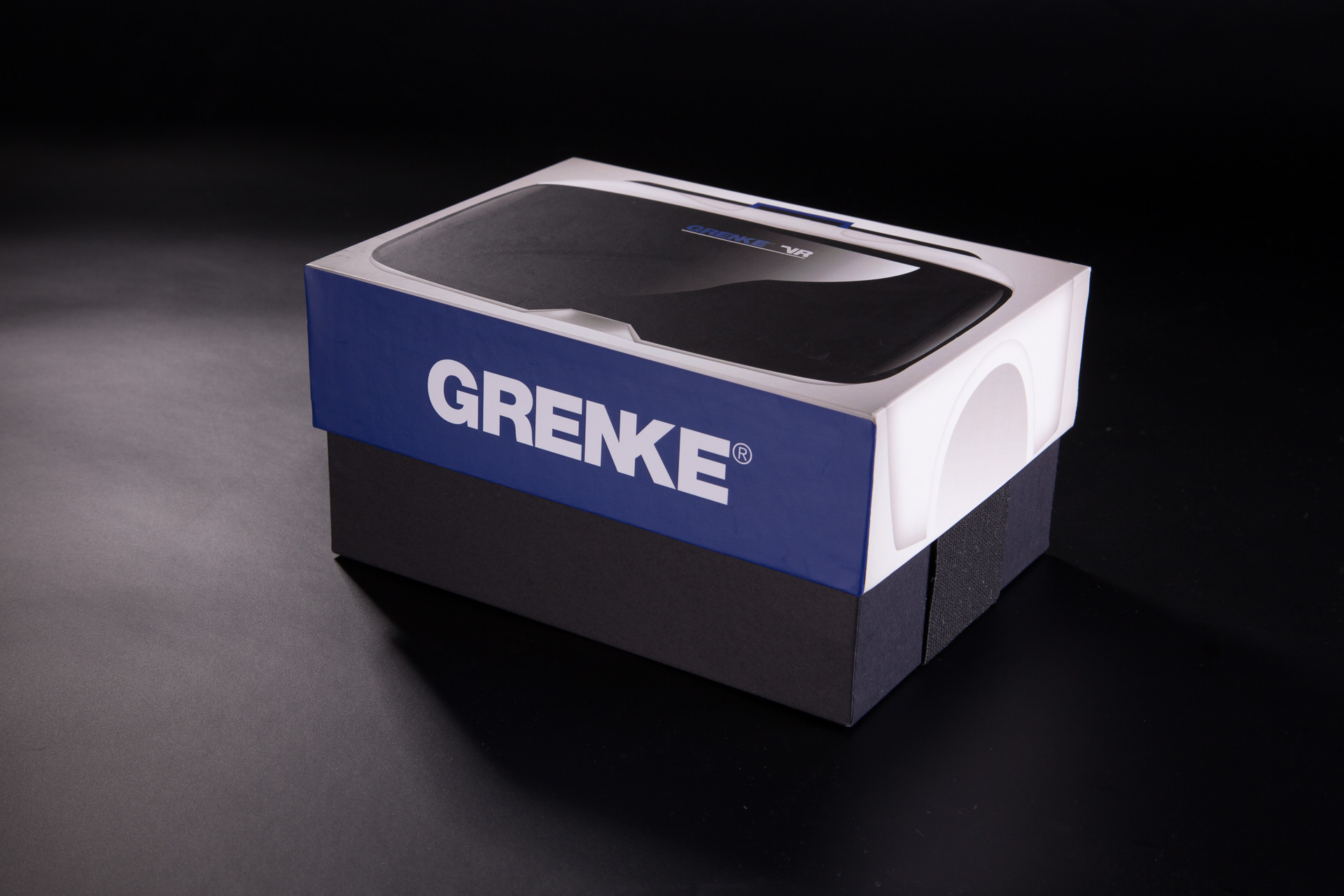

- electronics

- jewelry

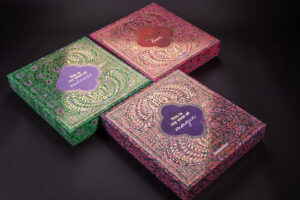

- gifts

- equipment and household items

- and many, many others.

The cardboard used for production is 1-3mm thick. Its thickness depends on the size, application, and customer preference.

The lid of the box can be of different heights. It can be high and cover the bottom entirely when applied.

It can also be lower and cover only part of the bottom. This makes it easier to open the box and reduces production costs.

For very light products, this solution is recommended, as lifting the box with one hand by the lid and the other by the bottom makes it easier to open. For products that weigh more than 100-200g, it no longer matters if the base sticks out. The bottom will slide out of the lid by itself, without the need to hold it with the other hand.

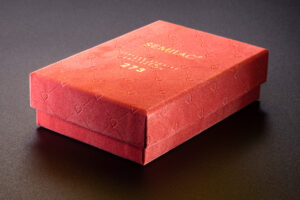

It is worth noting the differences in the appearance of CREASED and GROOVED boxes. Grooved boxes have sharp edges, while the top edge of the rigid boxes is rounded. Because of the technology used, rigid boxes are slightly less expensive. You can learn more about these techniques in the Wikibox tab.

INTERIOR OF THE BOX

The standard colors of cardboard are gray, white, and black. However, the box inside can be in a different color. This requires prior lamination of the cardboard with colored or offset-printed paper. Other ways to decorate the inside of the box include hot-stamping or screen printing.

INNER WRAPS

An important feature of the box interior is the length of the inner wraps. The standard length is about 15mm. However, we can extend it, all the way to the bottom (up to a maximum of 60mm). This enlarges the surface of the cover and may affect the price, but it is often an advisable procedure. Especially when a innlays is planned to be inserted into the box. We often lengthen the inner wraps so that their edge hides under the innlay.

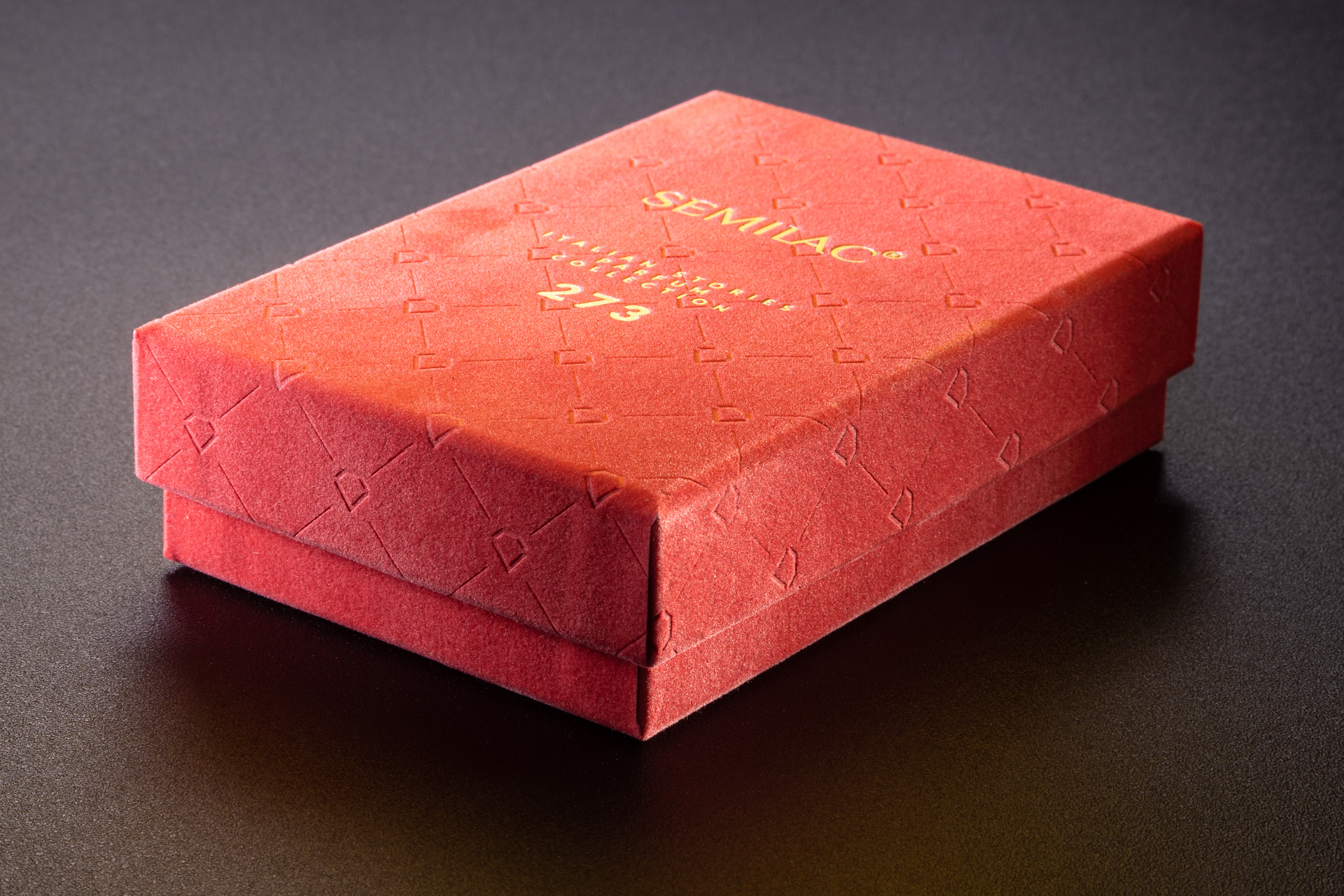

COVER MATERIALS

We use all available types of covers and printing methods, as well as enhancements. Information about covers can be found HERE.

BOX SIZE

Very important: it is assumed that the quoted box size is the INTERNAL size. The outer size may vary by more than a centimeter. This is due to the thickness of the materials, the necessary clearances, the thickness of the cover and of course, the type of box.

We follow this rule. If sizes other than internal are quoted, always indicate this.

Our machines allow us to make boxes of the following sizes:

– minimum 55x50x15mm

– maximum: 360x570x160mm or 420x2340x120

At the limits, there may be some restrictions on cardboard, cover, and others.

We can make other box sizes by hand. However, you should be aware that manual wrapping is more expensive than automatic wrapping, especially for taller ones.

ADD-ONS

Separate elements are various cutouts or ribbons that make it easier, for example, to take the product out of the box or to open it.

This is an item that is separately calculated and we ask you to indicate this when making inquiries. Our design and sales department will be happy to answer such questions. You can read more about additional elements HERE.